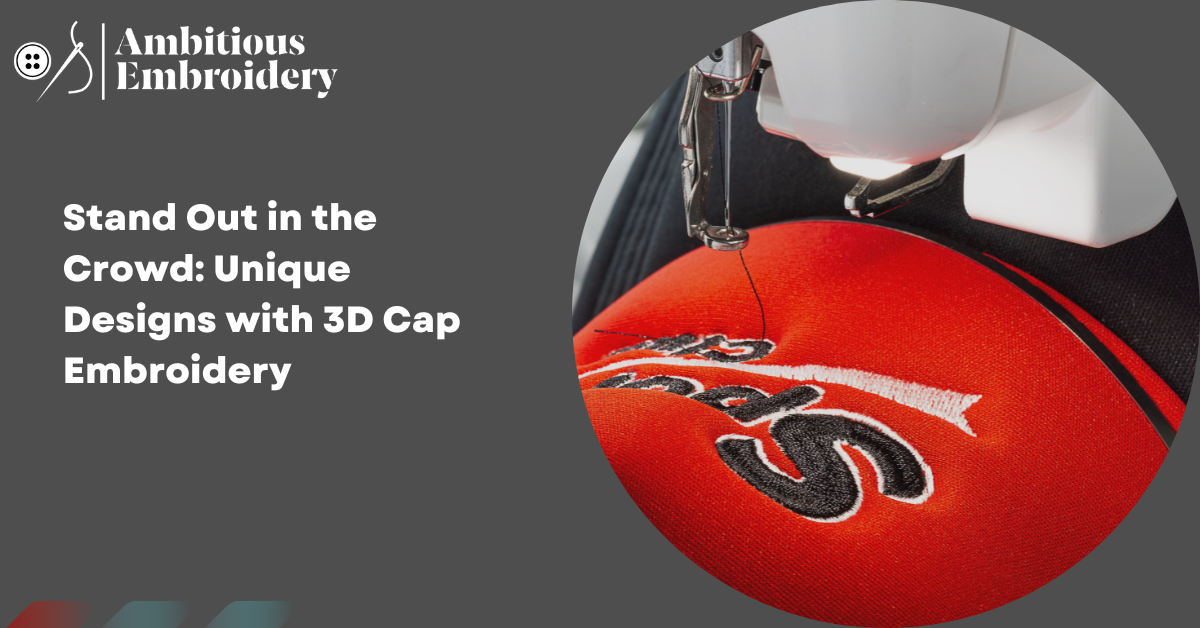

In a world where fashion trends come and go, standing out in the crowd can be a challenge. One surefire way to make a statement is through unique, customized apparel. At Ambitious Embroidery, we believe in the power of personalization, and nothing says “unique” quite like 3D cap embroidery. This innovative technique not only adds texture and depth to your designs but also transforms ordinary caps into extraordinary pieces of art.

What is 3D Cap Embroidery?

3D embroidery, also known as puff embroidery, involves stitching foam under the thread to create a raised, three-dimensional effect. This technique is perfect for adding a bold and eye-catching element to your caps, making your logo or design literally stand out. The result is a textured, tactile design that adds a whole new dimension to your headwear.

Why Choose 3D Embroidery for Caps?

- Visual Impact: The raised effect of 3D embroidery instantly draws attention. Whether you’re promoting a brand, supporting a team, or expressing personal style, 3D embroidered caps make a lasting impression.

- Durability: The added foam and extra stitching make 3D embroidery highly durable. These designs withstand the wear and tear of everyday use, maintaining their shape and vibrancy over time.

- Versatility: 3D embroidery is versatile and can be applied to a variety of cap styles, from snapbacks and trucker hats to fitted caps and beanies. This makes it an excellent choice for any occasion or purpose.

- Customization: With endless design possibilities, you can create something truly unique. From intricate logos and bold lettering to creative patterns, 3D embroidery allows for unparalleled customization.

The Process of 3D Cap Embroidery

Creating a stunning 3D embroidered cap involves several steps, each requiring skill and precision. Here’s a peek behind the scenes at Ambitious Embroidery:

- Design Preparation: We start by digitizing your design, converting it into a format that our embroidery machines can read. This step is crucial for ensuring precision and accuracy.

- Selecting Materials: High-quality foam and threads are chosen to match your design and the cap’s material. This ensures durability and a flawless finish.

- Stitching the Design: The foam is placed under the fabric, and the embroidery machine meticulously stitches over it, creating the raised effect. This requires careful attention to detail to maintain consistency and avoid flattening the foam.

- Finishing Touches: After the embroidery is complete, any excess foam is carefully trimmed away, and the cap is inspected for quality. The result is a beautifully crafted, three-dimensional design that stands out.

Real-Life Applications

3D cap embroidery is popular in various fields, from sports teams and corporate branding to fashion and personal use. Here are a few examples of how you can use this technique:

- Team Spirit: Create caps for your sports team with bold, raised logos that showcase team pride and unity.

- Brand Promotion: Enhance your corporate image with branded caps that feature your company’s logo in striking 3D embroidery.

- Fashion Statements: Design unique caps that reflect your personal style, whether it’s through intricate patterns, catchy phrases, or artistic motifs.

- Events and Giveaways: Make your events memorable with customized caps that attendees will cherish and wear long after the event is over.

Conclusion

In a sea of standard caps, 3D embroidered designs offer a refreshing way to stand out. At Ambitious Embroidery, we take pride in transforming your ideas into eye-catching, three-dimensional works of art. With our expertise and dedication to quality, you can trust us to deliver caps that are not only stylish but also durable and unique.